Emergency Packaging Equipment Repair Services: What to Do When Every Minute Counts

Emergency Packaging Equipment Repair Services: What to Do When Every Minute Counts

Blog Article

Discover Exactly How Packaging Tools Repair Work Services Work to Keep Your Operations Running Smoothly

Product packaging tools repair services are essential for maintaining the performance of production lines. These services not only diagnose concerns however also execute required fixings to avoid costly downtimes. Understanding how these repairs job can substantially impact operational performance. Yet, many businesses forget the indicators that suggest when fixings are required. Exploring the subtleties of these solutions reveals essential insights that can assist organizations stay competitive in a fast-paced market.

Recognizing the Significance of Packaging Tools Repair

Product packaging tools repair plays a critical function in keeping functional efficiency for businesses across different industries. The appropriate performance of product packaging equipment is vital for ensuring that products are packaged accurately and safely, which straight impacts high quality control and client satisfaction. When tools breakdowns, it can cause production delays, increased downtime, and potential monetary losses - Packaging Equipment Repair Services. Normal maintenance and punctual fixings help to minimize these threats, allowing business to maintain performance degrees and adhere to shipment schedules.Furthermore, skilled specialists can recognize underlying concerns before they escalate right into substantial troubles, thereby expanding the life expectancy of the equipment. This positive approach not only reduces repair work prices in the lengthy run however likewise enhances the general safety of the office. By prioritizing packaging tools repair work services, businesses can assure that their procedures run smoothly, ultimately supporting their development and competitiveness in the marketplace

Common Kinds Of Packaging Devices and Their Features

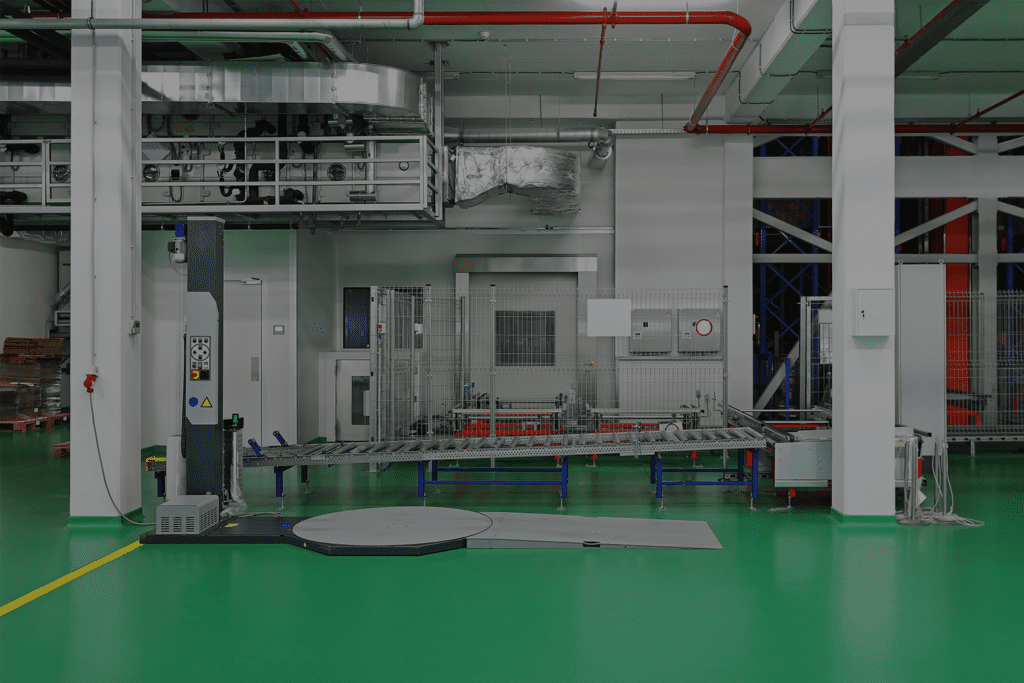

A varied selection of tools is utilized in the packaging procedure, each serving distinct features to boost effectiveness and item stability. One usual type is the filling maker, which accurately dispenses fluids or solids into containers, ensuring consistent quantity. Securing makers follow, applying heat or pressure to protect bundles and avoid contamination. Classifying machines are likewise essential, as they apply product info and branding, which is necessary for compliance and customer recognition. In addition, cartoning equipments automate the process of putting products into boxes, enhancing packaging operations. Stretch wrappers and shrink wrappers are used for palletizing goods, giving stability throughout storage space and transportation. Lastly, examination systems assure quality assurance by discovering issues or incongruities in packaging. Each of these machines plays a crucial role in preserving a reliable workflow, reducing manual work, and making certain that products get to customers in excellent problem.

Indications That Your Packaging Devices Needs Repair Work

When production efficiency lowers or product high quality falters, it usually suggests that product packaging tools requires attention. Numerous indicators can identify the requirement for repair service. Unusual noises, such as grinding or screeching, typically suggest mechanical concerns that might bring about added damages. Constant jams or imbalances during operation can interfere with workflow and signal that parts are put on or malfunctioning. Furthermore, irregular product packaging outcomes-- such as poorly secured bags or mislabeled items-- can indicate issues with the equipment's calibration or performance. An increase in downtime, requiring more constant troubleshooting, is one more indication of underlying concerns that require dealing with. Visible wear and tear, like torn belts or deterioration, can compromise devices efficiency. Acknowledging these signs early can stop costly interruptions and guarantee that packaging procedures run efficiently and successfully.

The Duty of Preventive Maintenance in Packaging Workflow

Efficient precautionary maintenance is crucial for making certain optimal efficiency in product packaging procedures, as it reduces the risk of devices failing and boosts general efficiency. By executing a structured maintenance routine, companies can identify prospective problems prior to they escalate into substantial issues. Routine inspections, lubrication, and component substitutes are important elements of this process, guaranteeing that machines operate at peak levels.Additionally, precautionary maintenance can cause minimized downtime, permitting continuous manufacturing circulation. By attending to deterioration proactively, organizations can expand the lifespan of their tools and avoid expensive fixings. This technique not just improves efficiency yet additionally fosters a safer working environment by decreasing the probability of mishaps brought on by malfunctioning equipment. Ultimately, a dedication to preventive maintenance is a strategic financial investment that supports the lasting success and dependability of packaging operations, lining up with business goals for efficiency and productivity.

Emergency Situation Repair Work Solutions: When Time Is important

Just how promptly can a packaging operation recoup from unexpected devices failure? In such critical circumstances, emergency situation fixing services play an important function. These solutions are created to react swiftly, often within hours, making certain very little downtime. Service technicians are generally on-call and furnished with the essential devices and components to deal with a range of tools breakdowns - Packaging Equipment Repair Services. This fast action is crucial for maintaining production routines and preventing expensive delays.Emergency repair services frequently include a thorough diagnostic procedure, allowing professionals to recognize the source of the failure quickly. As soon as detected, repair services can be executed effectively, bring back equipment capability. Furthermore, several providers offer 24/7 assistance, guaranteeing that aid is available whenever an emergency situation occurs. By prioritizing rapid feedback and specialist solution, packaging procedures can considerably alleviate the influence of unexpected breakdowns, inevitably supporting recurring productivity and operational reliability

Selecting the Right Packaging Equipment Repair Work Company

The Advantages of Routine Maintenance and Timely Services

Regular maintenance and prompt repair services of product packaging equipment give considerable benefits for organizations. These methods not just boost devices long life but likewise lower downtime expenses, bring about improved functional effectiveness. By prioritizing maintenance, business can guarantee smoother procedures and better resource monitoring.

Improved Devices Longevity

While numerous organizations concentrate on optimizing performance, overlooking routine maintenance and timely repairs can lead to raised expenses and equipment failings. Routine maintenance is important for extending the lifespan of packaging equipment (Packaging Equipment Repair Services). It enables operators to recognize and address possible concerns before they intensify, therefore protecting the honesty of the machinery. Prompt repairs not just bring back functionality yet likewise protect against wear and tear that can arise from long term overlook. By purchasing regular upkeep, companies can guarantee that their tools operates at peak efficiency, decreasing the risk of malfunctions. Boosted equipment longevity adds to set you back savings in the lengthy run, as it reduces the demand for frequent substitutes and assists keep a find here constant operations, consequently supporting total operational efficiency

Decreased Downtime Prices

Efficient upkeep and timely repair work considerably reduce downtime prices for businesses depending on product packaging equipment. When equipment experiences unexpected breakdowns, the monetary effect can be considerable, impacting production routines and profit margins. Regular upkeep helps determine potential issues before they escalate, making certain that tools runs effectively and regularly. By resolving minor repairs immediately, organizations can avoid costly disruptions and reduce the danger of prolonged downtime. This positive method not just supports a stable operations yet also cultivates a foreseeable functional budget plan. Eventually, investing in upkeep and fixing services cultivates a resistant manufacturing setting, where organizations can maintain their affordable edge, reduce economic losses, and preserve client complete satisfaction by supplying products promptly.

Enhanced Operational Efficiency

Timely repairs and regular maintenance play a crucial role in boosting functional performance for services making use of packaging equipment. Routine upkeep assurances that makers run at peak levels, minimizing the likelihood of malfunctions that can interfere with production processes. When devices is well-maintained, it can function extra reliably, bring about boosted outcome and uniformity in product quality. In addition, timely repair work reduce the risk of comprehensive damages, which often causes pricey substitutes and prolonged downtimes. By prioritizing repair and maintenance services, businesses can streamline their operations, eventually causing cost savings and improved performance. This proactive technique not just prolongs the lifespan of the devices but additionally cultivates a more secure working setting, adding to general operational success.

Regularly Asked Questions

Just How Swiftly Can I Anticipate Packaging Devices Fixing Solutions to Respond?

The rate of response from product packaging equipment repair service solutions can differ significantly. Generally, firms aim to address urgent demands within hours, while less crucial problems may take longer, reference depending on schedule and the complexity of the fixing required.

Are Product Packaging Equipment Repair Service Provider Available for All Equipment Brands?

Packaging devices repair work solutions normally deal with numerous equipment brands. Nonetheless, availability might vary based upon the company's knowledge and collaborations, making it necessary for drivers to confirm compatibility with their specific equipment prior to looking for support.

What Qualifications Should Technicians Have for Product Packaging Equipment Fixing?

Service technicians focusing on product packaging tools repair work typically have certifications in mechanical design or related fields, extensive hands-on experience, and knowledge of particular equipment brands, ensuring they can efficiently diagnose and deal with different tools problems.

How Can I Stop Future Malfunctions After Repair Services?

To stop future break downs, normal upkeep timetables ought to be developed, driver training stressed, and tools monitoring executed. These proactive procedures can substantially boost integrity and long life, reducing the possibility of functional interruptions and unexpected repairs.

What Is the Ordinary Cost of Packaging Equipment Repair Services?

The average price of packaging equipment repair services varies considerably, typically varying from $100 to $1,500, relying on variables such as devices kind, complexity of the issue, and needed parts or labor for the fixing. Product packaging devices repair solutions are important for maintaining the effectiveness of production lines. Routine maintenance and prompt fixings of product packaging tools give considerable advantages for companies. Effective maintenance and timely repair work considerably decrease downtime prices for companies counting on product packaging tools. Prompt repair work and constant upkeep play a crucial function in boosting operational effectiveness for services making use of product packaging devices. Packaging devices repair work services usually cater to various equipment brand names.

Report this page